OPTIMIZED GEOMETRY

The QUEEN BEE SERIES features optimized cutting geometries for steels under 58 HRC that ensure precise and exceptional surface quality in every application.

ADVANCED WAD COATING

Equipped with a new advanced WAD coating technology, the tools offer superior wear resistance and durability, significantly extending tool life even under demanding conditions.

VERSATILE PERFORMANCE

The QUEEN BEE SERIES provides reliable performance across a variety of applications, making it an indispensable tool for challenging machining tasks.

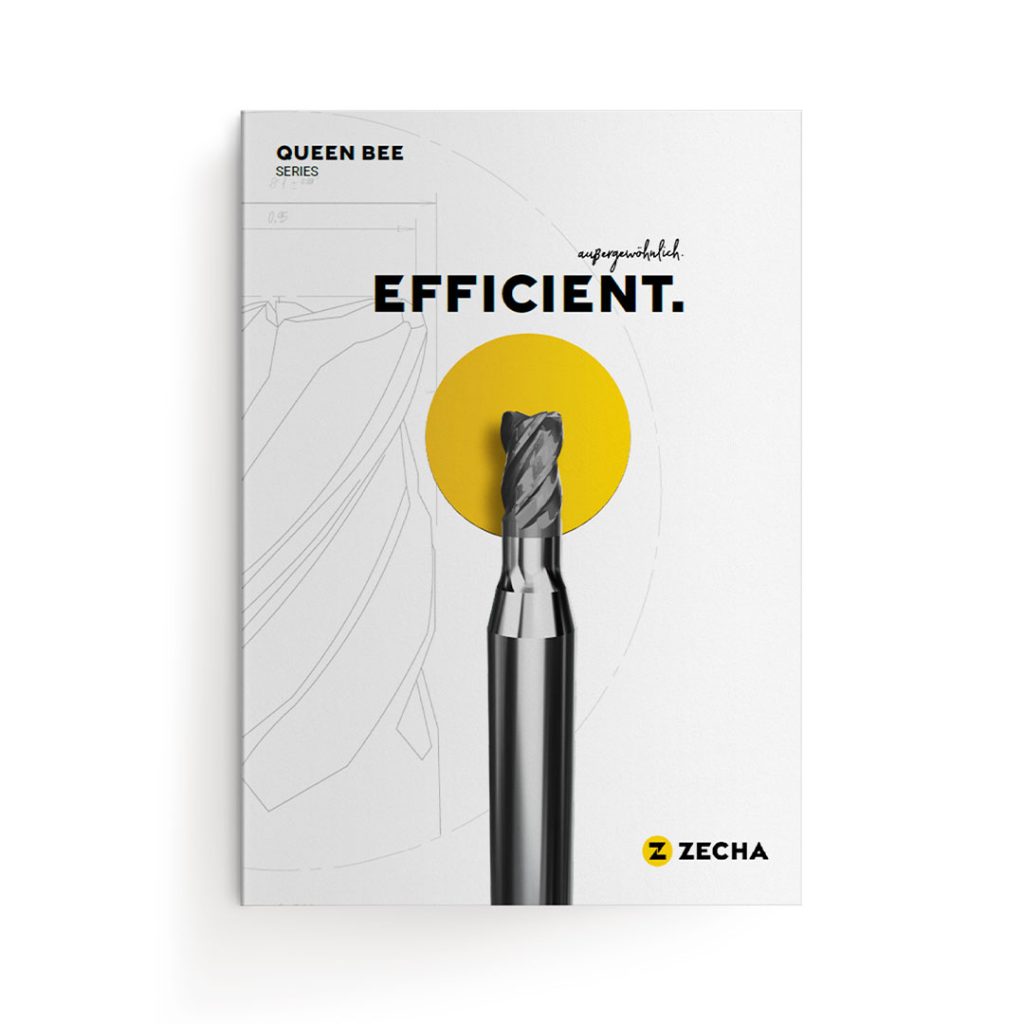

QUEEN BEE SERIES

PRECISION AND EFFICIENCY FOR TOUGH MATERIALS

Welcome to the QUEEN BEE SERIES, where advanced technology meets unparalleled precision and efficiency. Specifically designed for steels below 58 HRC, ZECHA’s QUEEN BEE tools combine optimized geometries with cutting-edge WAD coating technology to deliver exceptional performance and durability. Whether you’re involved in production, mold making, or general machining, the QUEEN BEE SERIES provides the reliability and versatility needed for even the most challenging applications. Discover how the QUEEN BEE SERIES can enhance your machining processes with superior quality and long-lasting precision.

OPTIMIZED GEOMETRY

Precision for Tough Materials

The QUEEN BEE SERIES is engineered with optimized, sleeker cutting geometries specifically designed for tough materials. This advanced design ensures efficient chip evacuation and reduces cutting forces, allowing for precise and clean cuts even in challenging materials. The optimized geometry of QUEEN BEE tools enhances performance and prolongs tool life, making them ideal for machining steels below 58 HRC. Experience the difference in quality and efficiency with QUEEN BEE’s innovative geometry, tailored for the most demanding applications.

UPDATED COATING

Enhanced Durability and Performance

The QUEEN BEE SERIES features an updated WAD coating that significantly enhances tool durability and performance. This advanced coating technology provides superior wear resistance, reducing friction and heat buildup during machining. As a result, QUEEN BEE tools maintain their sharpness and precision over longer periods, even in the most demanding conditions. The updated WAD coating ensures that your tools deliver consistent, high-quality results, extending tool life and improving overall efficiency.

SEE THE QUEEN BEE TOOLS IN ACTION

Curious about the QUEEN BEE tools’ performance? Click the button below to watch our QUEEN BEE tools in action milling a form out of Stavax on ZECHA’s YouTube page. See firsthand how the optimized tool line easily cuts through this notoriously difficult material.

QUEEN BEE

CASE STUDIES

In addition to the catalog, you can download detailed case studies from the QUEEN BEE SERIES. These case studies showcase various milling applications using QUEEN BEE tooling, providing in-depth analysis and cutting data for each step. Gain valuable insights into the performance and versatility of QUEEN BEE tools across different scenarios. Click the button below to access these informative case studies.

QUEEN BEE CATALOG

Explore the full range of QUEEN BEE tools by downloading our detailed catalog. The catalog highlights the key sales points of the QUEEN BEE SERIES and provides comprehensive information on all available sizes and geometries. Click the button below to access this essential resource and discover how QUEEN BEE tools can meet your precision machining needs.

OPTIONS FROM THIS SERIES

The carousel of tools below showcases the various geometry options available in the QUEEN BEE SERIES. Each tool is accompanied by icons that describe compatible materials, tool design details, and other key features. For a comprehensive understanding of these icons and their meanings, refer to the full list available in the QUEEN BEE catalog. Discover the perfect QUEEN BEE tool for your specific needs by browsing through the options below.

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Konigsbach-Stein

+49 7232 3022-0

info@zecha.de

Contact Page

Cutting Data Calculator